QUOTE(Wilhelm_I @ Aug 14 2008, 07:05 PM)

First of all learn to spell and take your time to create a proper reply because this is hard to read and you said 001 again which is obviously nothing!!!

Same here

0020 can be "over tightened", in general it is a bridged solder ball in the CPU/GPU/RAM area....

Also give some more information which X-Clamp Fix you used how many washers at all, where, if you drilled holes etc...

ok my gramma does suck though and my wireless keyboard drops letters from time to time . . Can a bridged solder ball be corrected ? the fault code i was refering to earlier in the thread was 0001 but i was only getting it whilst the pcb was in the chassis so i removed it and put the pcb in one of the pcb racks i have and i keep getting the 0020 code

heatgunning meathod used is vey much the same as yours but i use different materials to isolate the caps , instead of the foil plastic you use i use what we call pipe lagging . its to insulate pipes from freezing etc it is made up of a thickish foil on one side and bubble wrap on the other

the xclamp meathod i use involves two washers the same size one thin washer and one fiber washer a m5 x 12mm screw and a very good quality siver thermal paste correctly applied ( not to much )

i drill the chassis from the outside to take the screw

i place all 8 screws in place on the outside of the chassis and tape them to secure them

i then place the two same size washers on the screws inside the chassis ( the are around 2 tenths of a mm lower than the original pcb resting points , very little flex for the pcb )

i then place the pcb on top of the screws and washers

i then place the very thin metal washer om the screww and the fiber one on top ( they are the same hight as the top of the chips maybee a tiny bit over but when screwd down and compressed no flex is taking place )

this is it and i have done between 30 - 40 in 9 months and havent had one come back yet , i hope i have provided the info you need

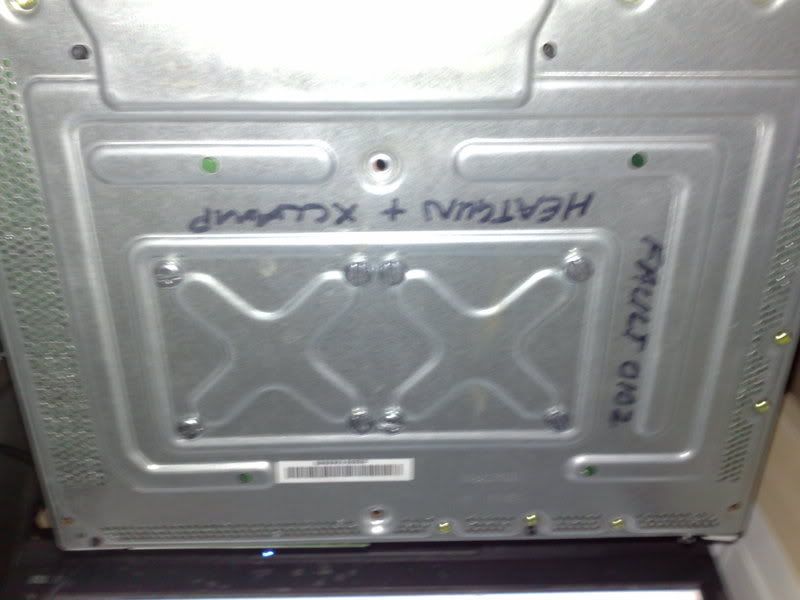

some pics of work and my box

Author

Topic: Faulty 360 (Read 225 times)

Author

Topic: Faulty 360 (Read 225 times)