well, im just using a sumbersable pond/aquarium pump i found on ebay. its called a jebao, im sure its something generic, but it serves its purpose well. its specs are as follows.

Model PP-388

Type Submersible

Size 2.10" x 2.0" x 2.4"

GPH (gallons per hour) 200

Approx. Max. Head Lift 5 ft

Watts (115v/60h) 12

Discharge Size 5/8" OD

Recommended Tubing Size 5/8" ID

Power Cord Length 6 ft

Manufacturers Warranty 1 Year

this is an image of it. its so compact it was awsome for its purpose. i absolutely love it.

salemoreforless is the seller with 99.3 % positive feedback.

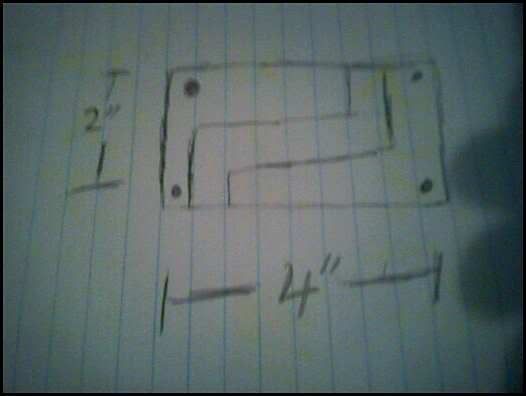

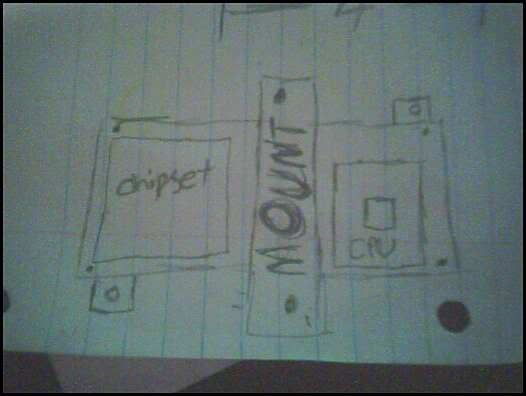

also, my grandfather an i took a good portion of the afternoon figuring out how to design the block. he though smaller id tubing was the way to go, so we both had to sacrifice a little bit settling with 3/8" id barbs. with the cpu and its chipset being so close together we decided to go with one large block instead of two. since we are using two 1/2" thick bars of 6061 aluminum that will be bolted together i think it will work well, considering this isnt a cutting edge computer or anything. also we went with one large channel running the length of the block with two outlets on each side. its a mixture of cross drilling and routing. ive made a few very rough concept sketches.

top veiw of the tunneling on the block. both top and bottum sides will be routed.

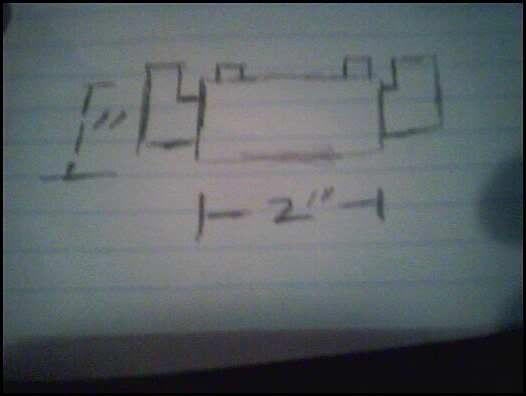

side view.

finally, with the addition of the large block i will have not trouble mounting like i would have with two smaller blocks. ill just be able to use the existing holes in the mainboard.

in closing, i had to help a friend this evening, so i couldnt get a dremel. tomorrow ill have to find a 3/8" npt pipe tap so we can complete the blocks hopefully by tomorrow evening. in addition, i was curious as to how i was going to be able to use an xecutor 3 chip i had installed on a v1.0 that had broken, and the i realized. the box that i play xbox live on has already had an x2.6 on it. so all ill have to do is add the chip, and reflash a 1.6 bios. all the apps are already installed. chances are once i finish the case ill work on a dual hdd mod with a 250gig. does anyone know how hard it is to reflash a bios like that, or if its even possible? i usually stay away from the software part of xbox modding. untill tomorrow hopefully.

-haloloser-

Author

Topic: Project Wetbox Wip (Read 4596 times)

Author

Topic: Project Wetbox Wip (Read 4596 times)